Casting industry is now used in the casting process is very much, of which the tidal mold sand casting process is most important to use the most extensive.

Tidal mold sand casting process can be divided into: casting mold preparation - the core - modeling - melting pouring - sand - a simple clean

- finishing - the final test This is the most important part of the production line is the shape part, because the modeling part will affect the back of the casting and finished the effect.

Now many foundries still follow the old hand-made method of making, so many foundries are now facing some of the same problems

Including: 1, please people difficult, no one is willing or no one will do

2, the efficiency is very low, affecting the production and enterprise development and profits

3, hand modeling slow, high cost, precision is not high, the quality of finished products as the machine

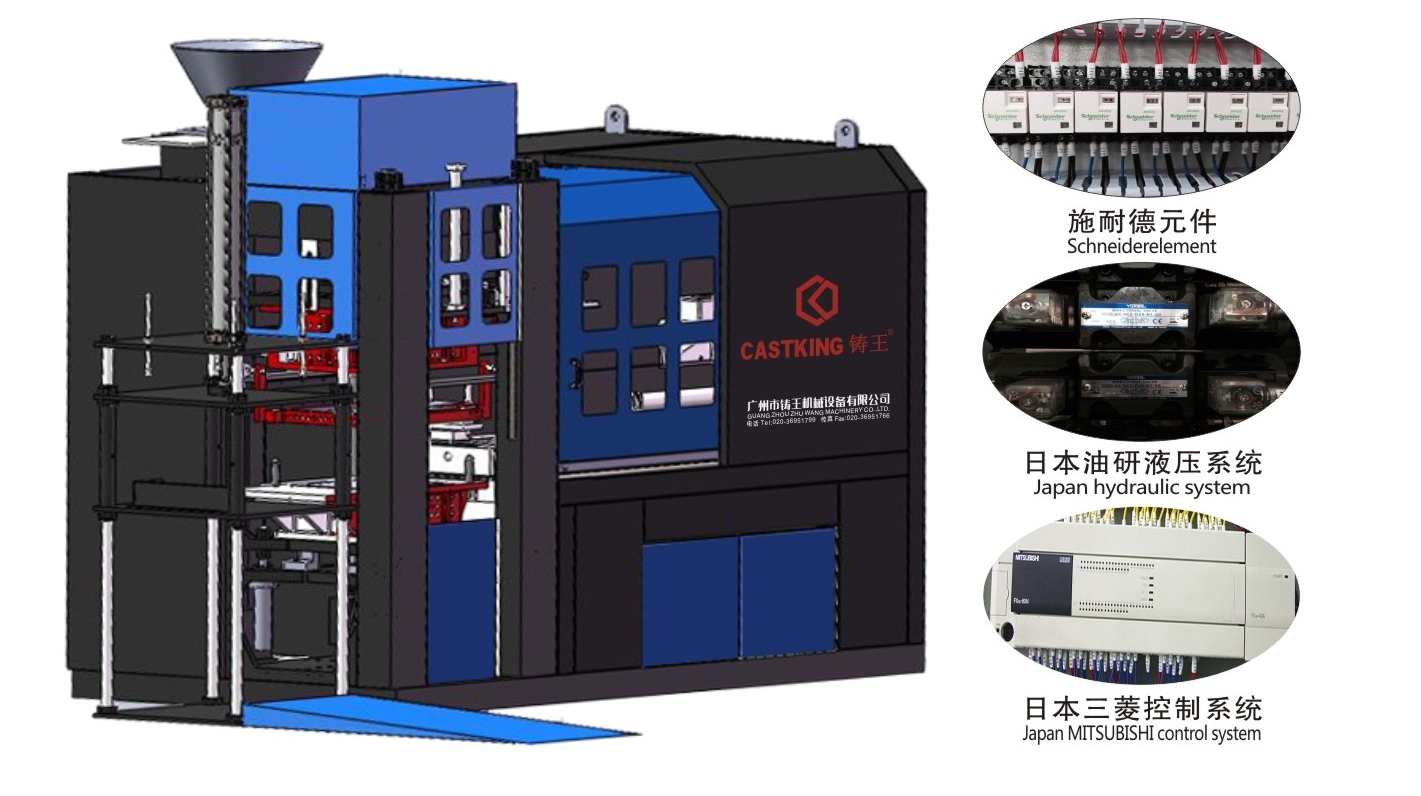

In addition to the above three questions, there are some other problems on the casting modeling, there are still many problems, we are produced by the Guangzhou Wang Wang automatic level of modeling machine is to solve the man-made era of casting industry problems , The use of our automatic level of the molding machine can be difficult, really for the majority of the foundry industry benefits, not just the profits so simple.

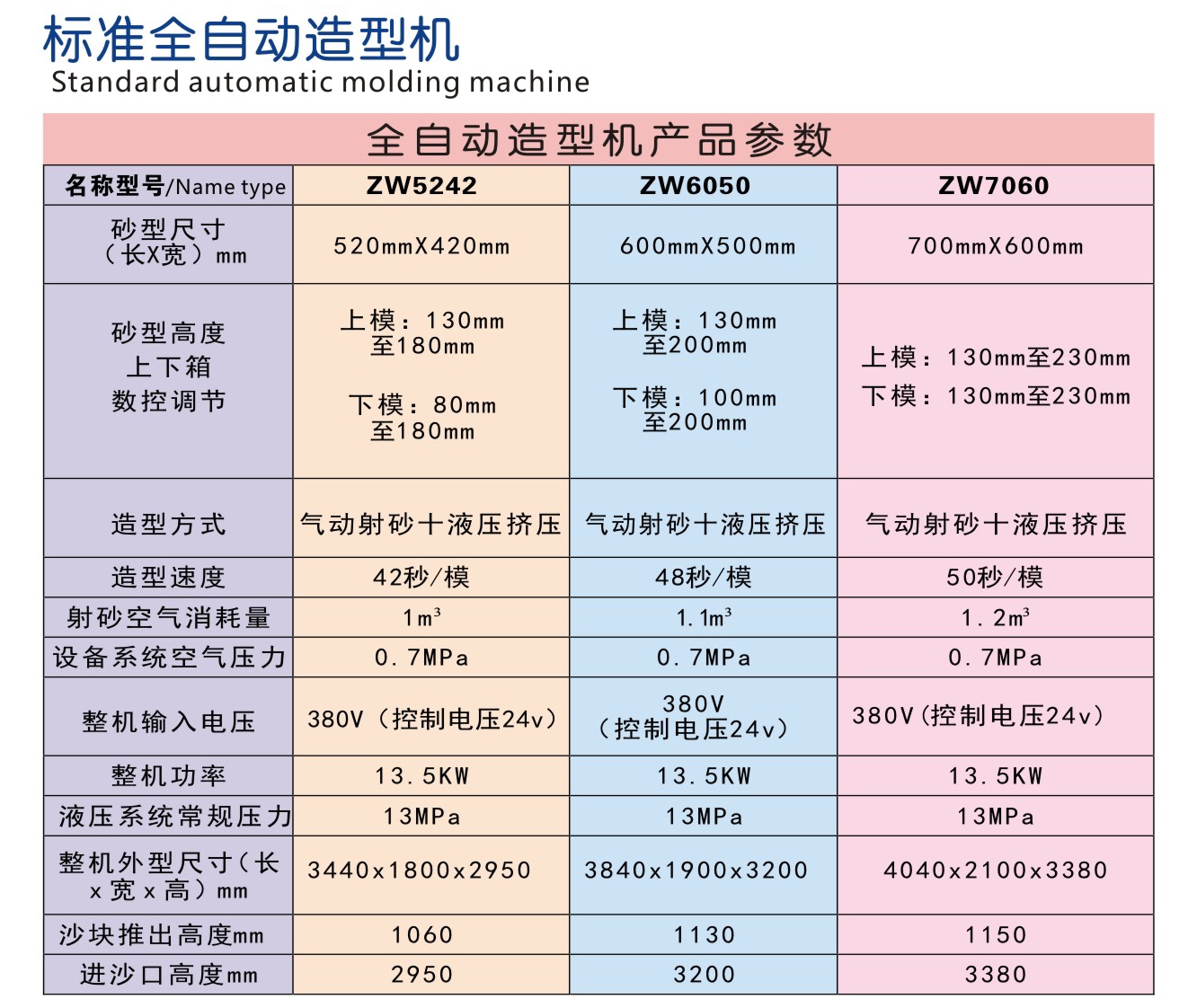

We cast the king produced by the level of automatic molding machine: the level of sub-type casting, the next core convenience, stripping more convenient, 1 hour 80 boxes, pouring mouth can be set according to your product, which we do regular size 4, Can also be customized according to customers.

If you have any of the above problems, or have more questions for the unresolved, you can call us to find a customized phone 13926261144 your company's molding machine, all meet your requirements of the personalized molding machine.